Ionic Liquid Applications: Revolutionizing Chemical Processes

Unleashing Potential: Where Ionic Liquids Transform Industries

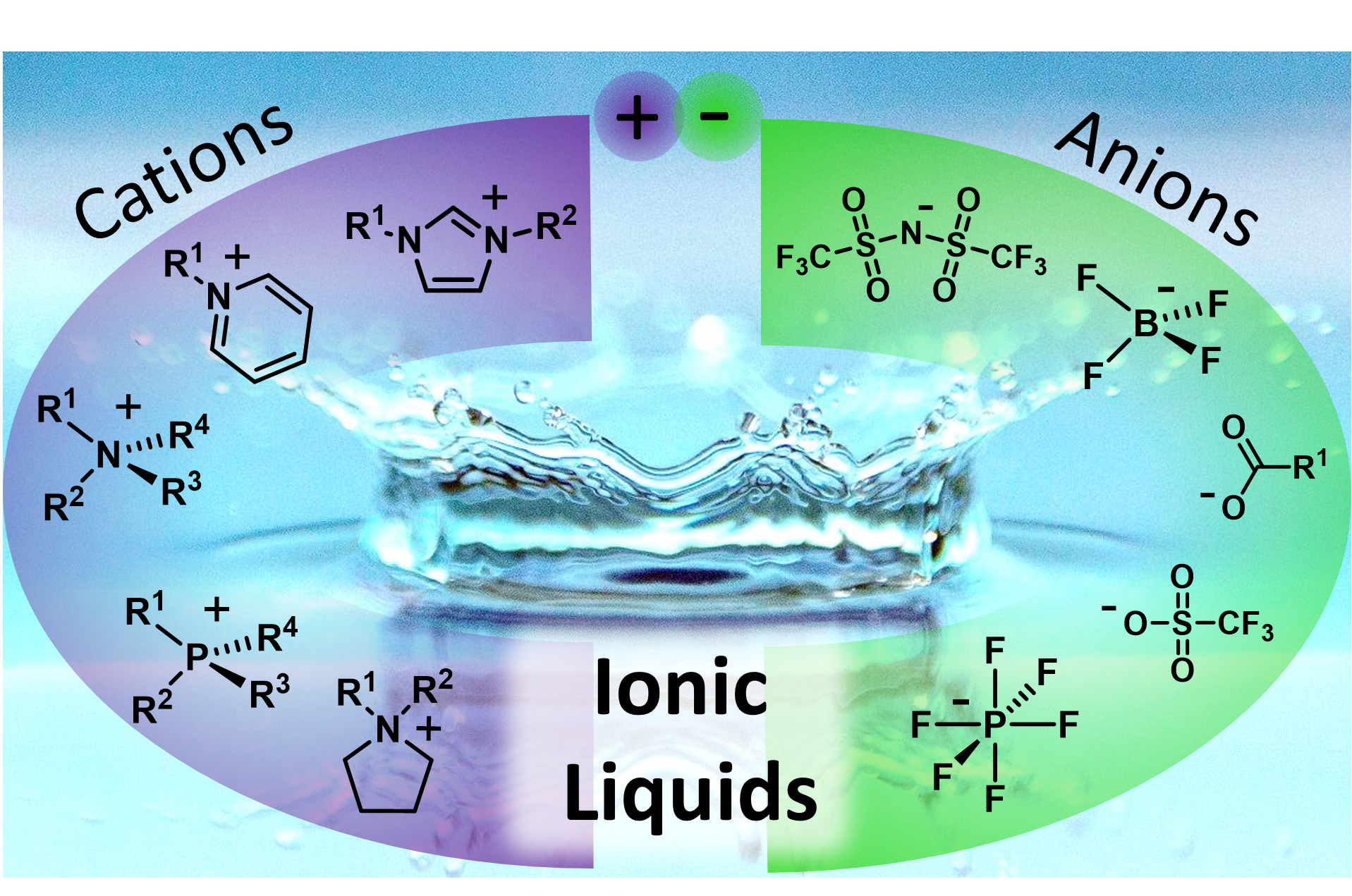

Ionic Liquid have evolved from lab curiosities to industrial catalysts. Building on their unique properties , these designer solvents now solve real-world challenges. Their tunability allows engineers to customize solutions. This versatility modernizes manufacturing while advancing sustainability.

Revolutionizing Chemical Synthesis & Catalysis

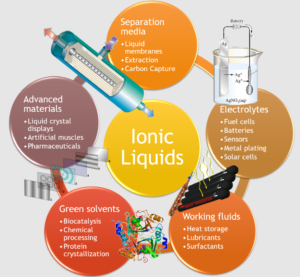

Ionic liquids transform chemical manufacturing as both solvents and catalysts. They improve critical reactions like polymerization, alkylation, and acylation. These processes are vital for pharmaceuticals and materials. ILs boost reaction speeds and selectivity significantly. They also enable higher yields under milder conditions. Product separation becomes easier too. Crucially, ILs replace conventional catalysts in esterification and hydrogenation. This reduces waste and costs. Discover our optimized catalysis solutions.

Mastering Separation & Purification

Ionic liquids excel at complex separations. Their tunable solvation resolves tough mixtures. For example, they separate close-boiling compounds efficiently. Environmentally, ILs capture CO₂ from industrial flue gases exceptionally well. This supports critical carbon management. Beyond emissions, they recover valuable metals from waste streams. They also process biomass by dissolving stubborn cellulose/lignin for biofuels.

Electrifying Electrochemical Applications

ILs redefine energy tech with superior conductivity. They serve as safer electrolytes in advanced batteries and fuel cells. This reduces combustion risks from organic electrolytes. Their charge-transfer properties may enhance solar cells. They also enable sustainable electrosynthesis.

Sustainable Materials & Recycling Solutions

ILs drive circular economy breakthroughs. They efficiently dissolve end-of-life tires for material recovery. This makes recycling uneconomical polymers viable. Their biomass valorization converts farm waste into chemicals. Specialized ILs also handle extreme tasks like nuclear material processing.

Embrace the Ionic Liquid Advantage

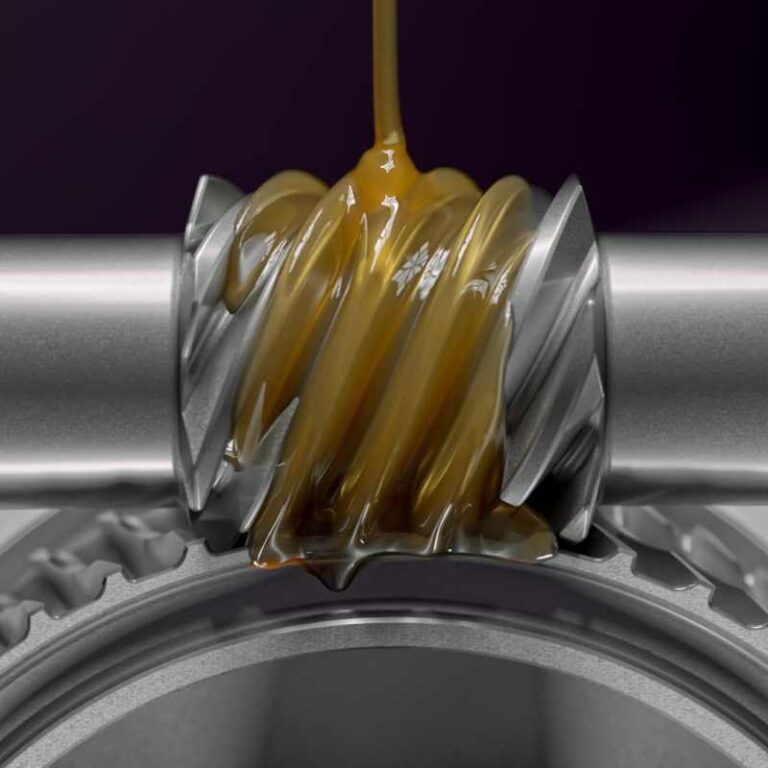

The innovation frontier for ILs keeps expanding. They show high promise in carbon capture systems for power plants. Low volatility and CO₂ selectivity reduce energy use. As lubricants, their thermal stability protects equipment in heat extremes. Pharma uses ILs for greener API synthesis. Analysts apply them as novel separation media.Ionic liquids enable carbon-neutral manufacturing and next-gen energy storage. As customizable “designer solvents,” they solve efficiency, safety, and sustainability challenges. Research now focuses on scaling production and multifunctional systems. Integrating ILs today accelerates cleaner industrial processes.