Chloroacetyl Chloride: The Invisible Catalyst Powering Modern Industries

What Is Chloroacetyl Chloride?

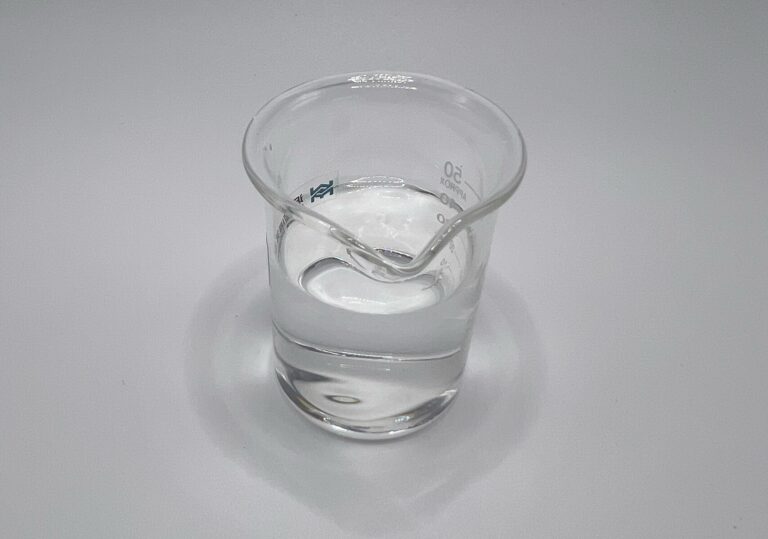

Chloroacetyl chloride (C₂H₂Cl₂O, CAS 79-04-9) is a highly reactive organic compound with a pungent odor. As a derivative of acetic acid, it serves as a versatile acylating agent—a substance that transfers chloroacetyl groups to other molecules. Its colorless to pale yellow appearance belies its critical role in synthesizing complex chemicals.

Industries favor chloroacetyl chloride for its efficiency in forming carbon-carbon and carbon-heteroatom bonds. According to a 2023 market report, the global demand for this compound grows at 4.2% annually, driven by its irreplaceable role in agrochemical and pharmaceutical production.

Key Industrial Applications

1. Agrochemicals: Safeguarding Global Food Security

Over 60% of chloroacetyl chloride is used to produce herbicides like alachlor and butachlor, which protect crops from weeds. These herbicides are vital for large-scale farming, particularly in rice and soybean cultivation. The compound’s reactivity allows for precise molecular modifications, enhancing herbicide efficacy while reducing environmental persistence.

For insights into sustainable agrochemicals, visit our Agrochemical Innovations Portal (internal link).

2. Pharmaceuticals: Enabling Life-Saving Drugs

In the pharmaceutical industry, chloroacetyl chloride acts as a precursor for APIs (Active Pharmaceutical Ingredients). It’s instrumental in synthesizing:

-

Antibiotics (e.g., cephalosporins)

-

Antimalarials (e.g., chloroquine derivatives)

-

Cardiovascular drugs

A 2022 study in the Journal of Medicinal Chemistry highlighted its role in accelerating drug development by simplifying complex synthesis pathways.

3. Dyes and Specialty Chemicals

The compound’s ability to form stable bonds with aromatic rings makes it ideal for producing vibrant, fade-resistant dyes. It’s also used in:

-

Polymer crosslinking agents

-

Flame retardants

-

Photographic chemicals

Safety and Handling: A Priority for Industries

Chloroacetyl chloride’s reactivity demands stringent safety measures:

-

Storage: Under inert gases (nitrogen/argon) to prevent hydrolysis.

-

PPE: Chemical-resistant gloves, goggles, and fume hoods are mandatory.

-

Regulations: Complies with EPA, REACH, and OSHA guidelines (EPA.gov reference).

Spills require immediate neutralization with alkaline solutions (e.g., sodium bicarbonate).

The Future of Chloroacetyl Chloride

With the rise of green chemistry, researchers are exploring:

-

Biodegradable alternatives for less toxic agrochemicals.

-

Catalytic processes to reduce waste in pharmaceutical synthesis.

For trends in sustainable chemistry, read our Green Chemistry Report (internal link).

Did You Know?

-

Chloroacetyl chloride was first synthesized in the late 19th century but gained industrial prominence only in the 1960s.

-

Its derivatives are found in over 120 patented pharmaceuticals.