Sebacic Acid – an overview

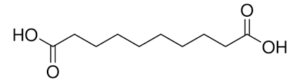

What is Sebacic Acid?

Sebacic acid (decanoic diacid, CAS 111-20-6) is a naturally derived dicarboxylic acid obtained from castor oil. This white flake/powder compound boasts exceptional thermal stability and biodegradability, making it indispensable for sustainable industrial solutions.

Production Excellence at Sincere Industries

As an ISO 9001-certified manufacturer, we utilize advanced hydrolysis and purification technologies to deliver 99.5%+ purity sebacic acid. Our vertically integrated supply chain ensures:

- Batch Consistency: Rigorous GC-MS testing guarantees uniform particle size and low ash content

- Eco-Conscious Processing: Zero-waste water recycling and carbon-neutral logistics

- Global Compliance: REACH, FDA, and Halal/Kosher certifications included

Industrial Applications

1. Biodegradable Plastics

Sebacic acid is pivotal in manufacturing:

- Bio-Polyesters: Enhanced flexibility for compostable packaging films

- Engineering Plastics: Heat-resistant automotive components (e.g., cable insulation)

- Medical Polymers: FDA-approved surgical sutures and implant coatings

2. High-Performance Nylon Synthesis

As a precursor for Nylon 610 and 510, our sebacic acid enables:

- 30% higher tensile strength vs. petroleum-based alternatives

- Superior moisture resistance in textile fibers and 3D printing filaments

- Reduced shrinkage in industrial gears and bearings

3. Next-Gen Lubricants & Cosmetics

- Synthetic Esters: Hydrolytic stability in aviation turbine oils (-40°C to 200°C operation)

- Skin-Compatible Emollients: Non-comedogenic properties for acne-safe moisturizers

Hair Care Innovations: pH-balancing agent in vegan hair serums

Optimal Storage Solutions for Sebacic Acid

Proper storage is critical to maintaining sebacic acid’s industrial efficacy and chemical integrity. Based on global standards and empirical research:

- Environmental Controls

- Temperature & Humidity: Store below 25°C with relative humidity 35–75% to prevent hydrolysis or caking

- Light Sensitivity: Use opaque containers or UV-resistant packaging; photodegradation accelerates above 30°C

- Temperature & Humidity: Store below 25°C with relative humidity 35–75% to prevent hydrolysis or caking

- Contamination Prevention

- Isolate from oxidizers, acids, and toxic substances; cross-contamination risks catalytic decomposition.

- Industrial-scale bulk storage requires nitrogen-inerted tanks to inhibit oxidation.

- Handling Protocols

- Use sealed containers (HDPE-lined drums) for powder forms; liquid formulations demand corrosion-resistant tanks.

- Transport with desiccant packs and moisture barriers – absorption exceeding 5% degrades thermal stability.

- Shelf Life & Compliance

- Certifications: REACH/FDA-compliant packaging extends shelf life to 36 months.

- Traceability: Blockchain-tracked batches ensure audit-ready quality documentation.

Why Partner with Us?

A. Technical Collaboration

Our R&D team provides:

- Custom esterification support for novel copolymer development

- SDS documentation with 24-hour regulatory assistance

- Sample optimization for viscosity/pH-specific requirements

B. Supply Chain Advantages

- 5,000+ MT annual capacity with JIT global delivery

- Dedicated storage tanks for bulk liquid shipments

- Blockchain-tracked quality documentation