Application of Dimethylethanolamine (DMEA) as a Catalyst in Polyurethane Systems

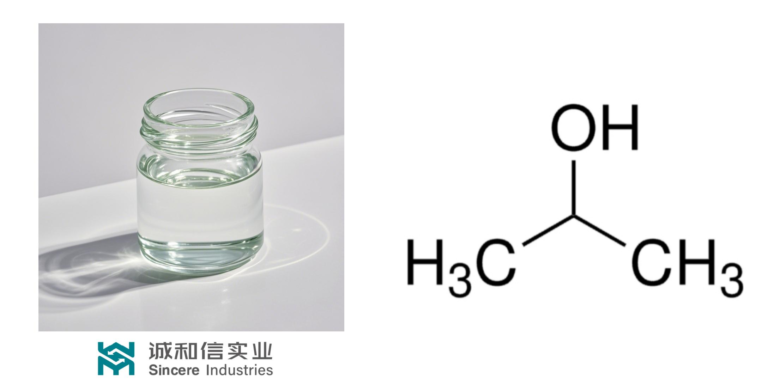

1. Introduction to Dimethylethanolamine (DMEA)

Dimethylethanolamine (DMEA, CAS No. 108-01-0) is a tertiary amine compound containing both amine and hydroxyl functional groups. Due to its balanced reactivity and good compatibility, DMEA is widely used in polyurethane, coatings, surfactants, and other fine chemical applications.

In the polyurethane industry, DMEA is commonly used as an amine catalyst or reaction auxiliary, playing an important role in controlling reaction kinetics and optimizing material performance.

2. Catalytic Role of DMEA

The core reaction in polyurethane production involves the reaction between isocyanates (—NCO) and polyols (—OH), along with secondary reactions between isocyanates and water that generate carbon dioxide in foam systems.

As a tertiary amine catalyst, DMEA can:

-

Accelerate the gel reaction between isocyanates and polyols

-

Adjust reaction speed, reducing cream time and curing time

-

Improve process control during foam formation

The hydroxyl group in DMEA also contributes to better solubility and compatibility within polyurethane formulations, allowing for more uniform and controlled catalytic performance.

3. Applications of DMEA in Different Polyurethane Systems

3.1 In rigid polyurethane foam systems used for insulation materials, cold-chain applications, and pipeline insulation, DMEA is often applied as an auxiliary amine catalyst. Its benefits include:

-

Improved balance between blowing and gel reactions

-

More uniform cell structure

-

Enhanced dimensional stability and mechanical performance

3.2 Spray polyurethane systems require precise control of reaction speed and processing time. The use of DMEA helps to:

-

Fine-tune reactivity for better spray control

-

Promote dense and consistent foam structures

-

Improve adhesion and overall coating performance

3.3 In certain polyurethane coatings and adhesive formulations, DMEA can also function as a reaction modifier or neutralizing agent, helping to:

-

Control reaction rate

-

Improve storage stability

-

Optimize film formation or bonding properties

4.Advantages of Using DMEA as a Polyurethane Catalyst

Compared with other commonly used amine catalysts, DMEA offers several advantages:

-

Moderate and controllable catalytic activity, suitable for formulation optimization

-

Good compatibility with a wide range of polyurethane systems

-

Flexible application, either alone or in combination with other catalysts

-

Supports cost-effective formulation design while maintaining performance requirements

5. Conclusion

As polyurethane materials continue to expand in applications such as building insulation, cold-chain logistics, industrial protection, and functional coatings, the demand for stable and adaptable catalysts is increasing.

Dimethylethanolamine (DMEA), with its reliable catalytic performance and good formulation compatibility, remains a valuable amine catalyst option. When properly formulated, DMEA can contribute to improved processing efficiency and consistent end-product quality.