Tall Oil Fatty Acid (TOFA): A Versatile Industrial Ingredient

Overview

Tall Oil Fatty Acid (TOFA) is a byproduct of the kraft pulping process, derived from the treatment of pine wood. As a mixture of unsaturated and saturated fatty acids—primarily oleic, linoleic, and palmitic acids—TOFA serves as a cost-effective and renewable raw material for numerous industrial applications. Its unique chemical structure, combining a carboxylic acid group with a long hydrocarbon chain, makes it highly reactive and adaptable for chemical modifications.

Uses and Applications

TOFA plays a critical role across diverse industries due to its versatility. In the chemical sector, it is a key precursor for dimer acids, which are essential in producing polyamide resins for adhesives and inks. The paint and coatings industry relies on TOFA-based alkyd resins to enhance durability and drying properties. Additionally, TOFA derivatives act as emulsifiers in metalworking fluids, corrosion inhibitors, and even biofuel components. Its compatibility with other chemicals allows for tailored formulations, meeting specific performance requirements in everything from industrial lubricants to personal care products.

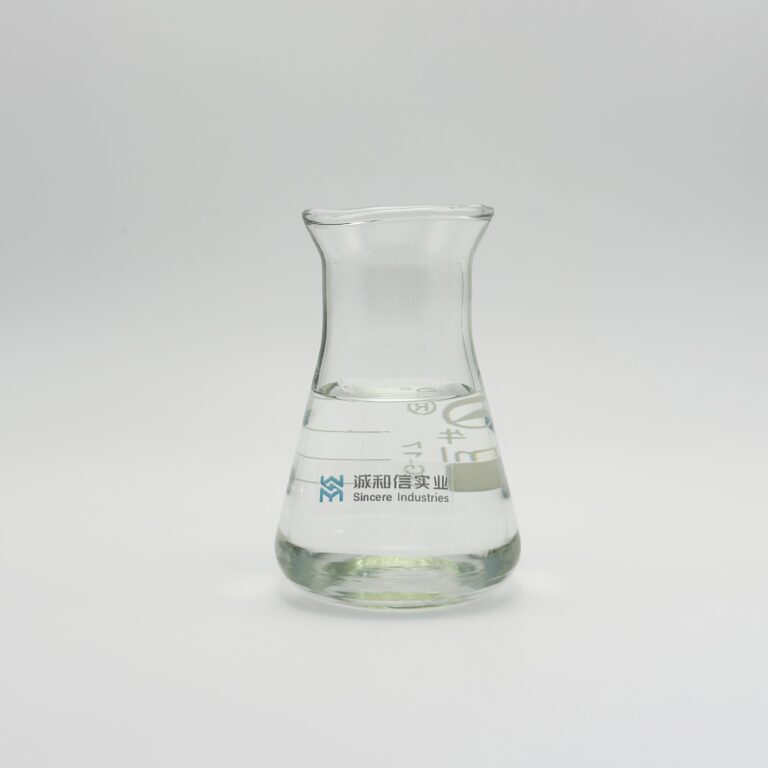

Physical and Chemical Properties

TOFA typically appears as a pale yellow to dark brown viscous liquid, with a characteristic pine-like odor. Its properties vary depending on the composition of fatty acids, but it generally exhibits a density of around 0.9 g/cm³ and a boiling point above 300°C. The presence of unsaturated bonds (measured by iodine value, often ranging from 120 to 180 g I₂/100g) contributes to its reactivity, making it suitable for polymerization and other chemical reactions. TOFA is insoluble in water but dissolves readily in organic solvents like ethanol and acetone.

Health Effects

While TOFA is not classified as highly toxic, exposure should still be managed carefully. Direct contact with skin or eyes may cause mild irritation, and inhalation of vapors or mists in poorly ventilated areas can lead to respiratory discomfort. Prolonged or repeated exposure without proper protection could result in dermatitis. Ingestion, though unlikely in industrial settings, may cause gastrointestinal distress. Safety Data Sheets (SDS) recommend using personal protective equipment (PPE) such as gloves and goggles when handling TOFA.

Environmental Effects

As a plant-derived material, TOFA is biodegradable, reducing its long-term environmental impact compared to petroleum-based alternatives. However, its release into aquatic systems can pose short-term risks to aquatic life due to the potential formation of surface films that limit oxygen exchange. Industrial discharges containing TOFA should be treated to minimize ecological disruption. The production process, tied to the pulp and paper industry, also raises sustainability considerations, prompting some manufacturers to adopt cleaner extraction methods.

Exposure and Risk Management Recommendations

To ensure safe handling, workplaces should implement engineering controls such as local exhaust ventilation to minimize airborne exposure. Storage containers must be kept tightly sealed in cool, dry areas away from oxidizing agents. Spills should be contained with absorbent materials and disposed of according to local regulations. Employee training on proper handling procedures and emergency response measures is essential. For formulators, substituting TOFA with refined or modified grades can reduce risks while maintaining performance.

Conclusion

Tall Oil Fatty Acid remains an indispensable resource for industries seeking sustainable, high-performance raw materials. Its broad applicability—from adhesives to biofuels—highlights its economic and functional value. By adhering to responsible handling practices and continuing to innovate in purification and modification technologies, manufacturers can further enhance TOFA’s safety and environmental profile. As demand for bio-based chemicals grows, TOFA is poised to play an even greater role in the transition toward greener industrial solutions.