Industrial Cleaning: The Role of DTPA in Cleaning Agents

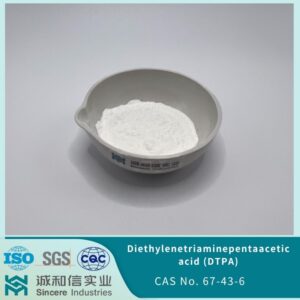

What is DTPA?

DTPA, or Diethylenetriaminepentaacetic acid, is a powerful chelating agent belonging to the polyaminocarboxylic acid family. It is a specialized chemical compound designed to form exceptionally stable, water-soluble complexes with a wide range of metal ions.

DTPA’s applications in five major industrial cleaning scenarios

The application of DTPA spans numerous critical industrial cleaning scenarios where metal ion contamination is a primary concern.

In the cleaning of boilers and heat exchangers, DTPA-based formulations are exceptionally effective at dissolving calcium carbonate and sulfate scales, as well as iron oxide deposits, which are notorious for impairing heat transfer efficiency and leading to energy loss and potential equipment failure. Within the membrane cleaning industry, particularly for reverse osmosis and nanofiltration systems. DTPA is indispensable for gently yet thoroughly removing foulants and mineral scales from the delicate membrane surfaces without causing damage, thereby restoring water flux and salt rejection performance.

In metal surface treatment, DTPA is used to prepare ultra-clean surfaces by efficiently chelating residual iron and other metal ions, which is a vital step before subsequent processes like plating, phosphating, or painting to ensure superior adhesion and quality.

For the dairy and food processing industries, DTPA helps clean equipment by effectively breaking down milk stone and other mineral-based deposits that are difficult to remove, ensuring hygiene and operational efficiency.

Finally, in the petrochemical sector, DTPA is employed to clean cracking furnaces and other equipment where coke and metal-catalyzed polymers build up, helping to restore efficiency and extend operational run times between shutdowns.

Why choose DTPA?

The decision to select it over other chemicals Its key strength lies in its ability to form more stable complexes with a broader spectrum of metal ions. especially ferric iron. Compared to more common chelants like EDTA (Ethylenediaminetetraacetic acid). This makes it the agent of choice for tackling the most challenging rust and scale problems. DTPA also demonstrates greater stability under conditions of high temperature. This thermal stability allows for its use in online cleaning procedures. Without the need for a complete system shutdown in some applications.

Conclusion

In conclusion, DTPA rightfully earns its title as a secret weapon in the arsenal of industrial cleaning. Persistent challenges in maintaining industrial equipment. Its versatility across a wide range of applications, from power generation to food processing, underscores its critical importance.