Triethylenediamine (TEDA): A Key Catalyst in Polyurethane Production

Introduction

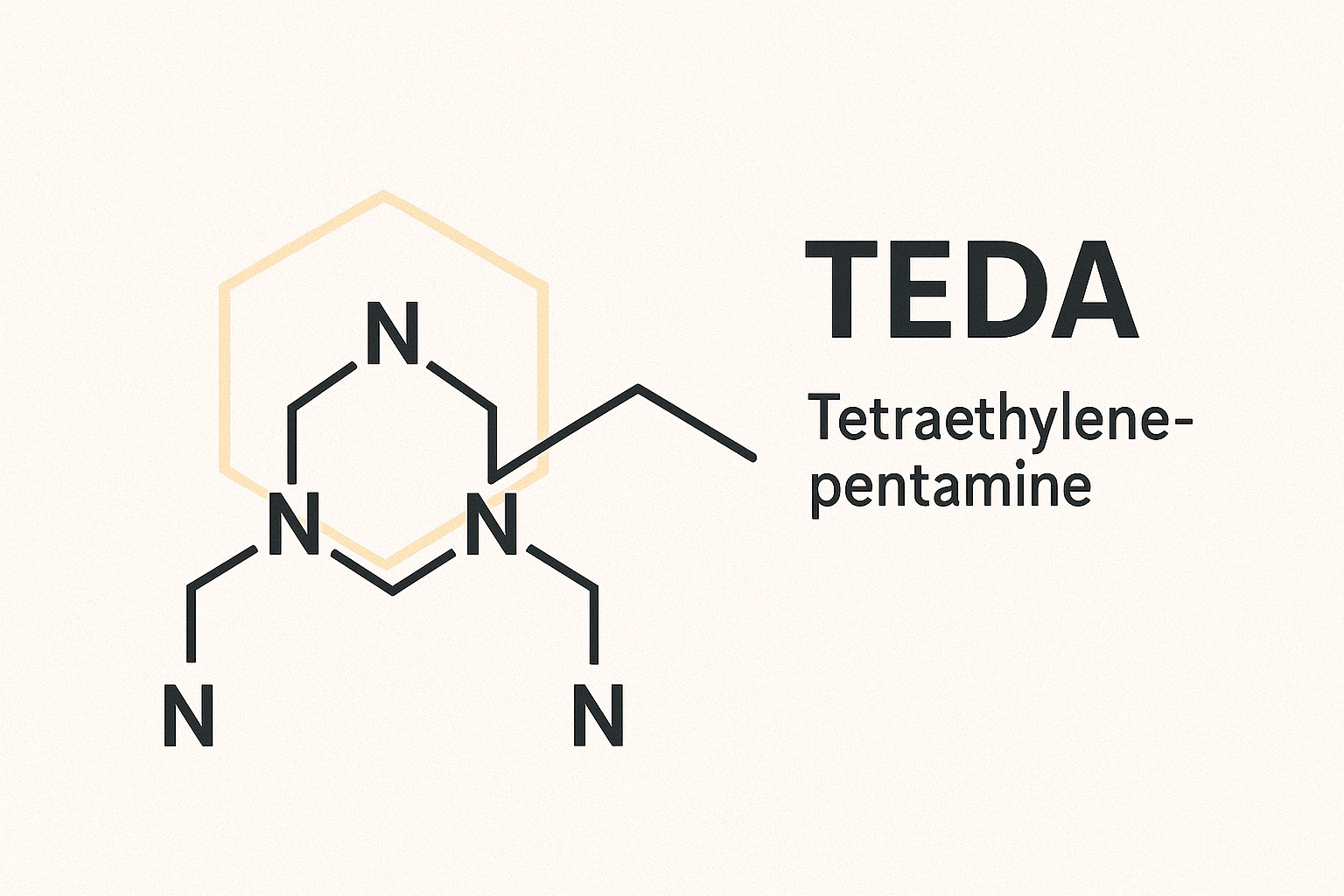

Triethylenediamine (TEDA), also known as 1,4-Diazabicyclo[2.2.2]octane (DABCO), is one of the most important and widely used tertiary amine catalysts in the polyurethane (PU) industry.

With its unique bicyclic amine structure, TEDA offers exceptional catalytic activity, providing precise control over both the gelling and blowing reactions during polyurethane formation.

Chemical Identity

| Item | Description |

|---|---|

| Chemical Name | Triethylenediamine |

| Synonyms | DABCO, 1,4-Diazabicyclo[2.2.2]octane |

| CAS No. | 280-57-9 |

| Molecular Formula | C₆H₁₂N₂ |

| Molecular Weight | 112.17 |

| Appearance | White crystalline solid or colorless liquid (when in solution) |

Catalytic Function in Polyurethane Systems

In polyurethane foam manufacturing, two major reactions occur simultaneously:

-

Isocyanate + Polyol → Polyurethane (Gelling reaction)

-

Isocyanate + Water → Urea + CO₂ (Blowing reaction)

TEDA acts as a balanced catalyst, effectively promoting both reactions while maintaining uniform cell structure, consistent rise profile, and excellent mechanical strength.

Its strong basicity ensures high catalytic efficiency even at low concentrations.

Product Forms

TEDA is available in different formulations to meet various processing needs:

-

Pure TEDA (crystalline solid) – used in systems requiring precise dosing and maximum activity.

-

33% TEDA solution in Diol – a convenient liquid form offering easy handling and stable performance.

-

Customized blends – tailor-made solutions based on specific polyurethane formulations.

Applications

TEDA and its solutions are widely applied across the polyurethane sector, including:

-

Flexible PU foam (furniture, automotive seating)

-

Rigid PU foam (insulation, construction panels)

-

Spray foam systems

-

PU coatings, sealants, and elastomers

Its versatility makes it an indispensable catalyst for both continuous and batch production processes.

Advantages

-

High catalytic activity with excellent control of reactivity balance

-

Consistent foam quality and fine cell morphology

-

Compatibility with a wide range of polyols and isocyanates

-

Stable performance under varying temperature conditions

-

Convenient handling when supplied as a pre-diluted liquid formulation

Storage and Handling

TEDA should be stored in tightly closed containers, away from moisture and direct sunlight.

When handling the pure crystalline form, avoid exposure to air to prevent absorption of carbon dioxide and water vapor.

Always follow the safety recommendations outlined in the MSDS.

Why Choose Us?

Hainan Sincere Industries is a reliable manufacturer and supplier of Triethylenediamine (TEDA) and 33% TEDA in Diol formulations.

We ensure:

-

Consistent product purity and stability

-

Flexible packaging options for different scale requirements

-

Technical support for formulation optimization

-

Global logistics service and prompt delivery

Our TEDA products are trusted by polyurethane system houses, foam manufacturers, and specialty chemical formulators worldwide.